Fujian Lenrate Industrial Co., Ltd.

Fujian Lenrate Industrial Co., Ltd. (hereinafter referred to as Lenrate) was established in 2013 with a registered capital of 50 million yuan. Its predecessor was the Xiamen Double Automobile Electrical Appliances Division, a high-tech enterprise in China dedicated to the research and development and manufacturing of automobile parts. Since its establishment, it now has more than 120 employees and covers an area of 6,000 square meters. Over the years, Lenrate has focused on product development and empowering advanced manufacturing. Its core products include automotive combination switches, functional switches, sensors, control units, etc., with an annual output of 1 million sets. Lenrate mainly serves more than ten well-known automobile manufacturers such as King Long, Golden Dragon, Dongfeng, and Huachen Xinyuan, and has become their core suppliers and strategic partners. Currently, some of Lenrate's products have been exported to more than 60 countries and regions overseas, becoming a leading enterprise in China's automotive electronic and electrical parts industry.

In recent years, Lenrate has continuously introduced advanced international research and development, production, testing and testing equipment, including 3D printing, high-precision mold processing complete sets of equipment, semi-automatic assembly lines, two-dimensional measuring instruments, three-coordinate measuring instruments, voltage resistance testers, constant temperature and humidity boxes, vibration test benches, high and low temperature impact test boxes, durability testers, etc. These features high automation, accurate product size and function, high measurement accuracy, strong test life, ensuring high performance and high reliability of products, realizing full traceability of modern production, and greatly enhancing the high-tech content of products.

Lenrate first passed the IATF16949 international management system certification in 2018 and registered 2 trademarks. It has now established a product research and development center, professional product testing center, and is currently setting up a technical center in cooperation with colleges and universities, which is progressing smoothly. The "lenrate" brand products independently developed by the enterprise have been highly recognized by customers.

At present, Lenrate's electronic and electrical products have become one of the most potential and competitive advanced enterprises in the automotive parts industry. Lenrate always insists on taking the mission of letting Chinese supporting automotive parts go out, focusing on the two major sectors of automotive electronics and electrical products, and expanding related products in the direction of automotive intelligence and new energy.

In the future, Lenrate will continue to carry out innovative mechanisms such as technological innovation, system innovation, management innovation, and process innovation, rely on continuous progress, and strive to create the most quality and strength in innovation. From Made in China to Intelligent Manufacturing in China, from China to the world, Lenate faces the same cause with the most competitive enterprises, growing together, achieving together, and achieving a win-win situation.

Established in

Cover An Area

Employee

Annual Output

R&D Strength

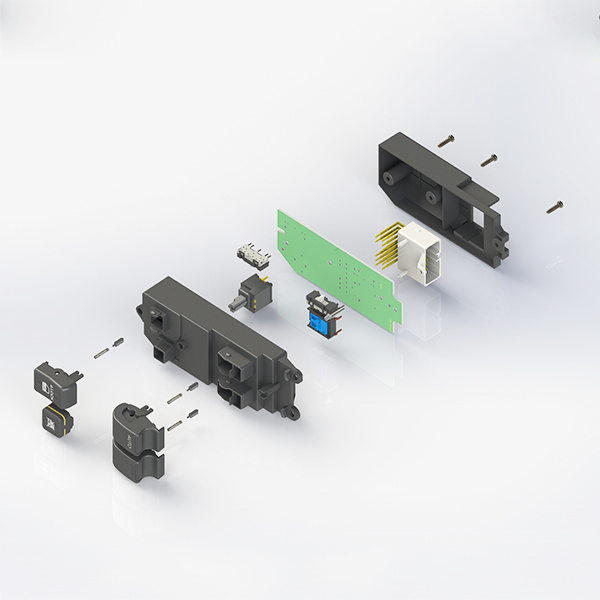

We have strong capabilities in the forward design, development, and validation of automotive electronics products. With a team of over 20 people, including project developers, electronic and electrical designers, structural designers, precision mold designers, and testing equipment developers, we have an independent research and development center and product laboratory. In terms of technology research and development, we focus on user needs, conduct technological innovation, drive industry upgrades, and enhance user experience.

Lenrate Industrial

According to customer requirements for appearance design, structural design, circuit design and finally output a product solution satisfactory to the customer

Lenrate Industrial

With the capacity of circuit schematic design, PCB design, sample trial production to batch PCBA production capabilities

Lenrate Industrial

Durability test is an important test for the product to verify the service life of the product during the design process. Different products use different durability testing workers in accordance with Chinese standards or international standards.

Lenrate Industrial

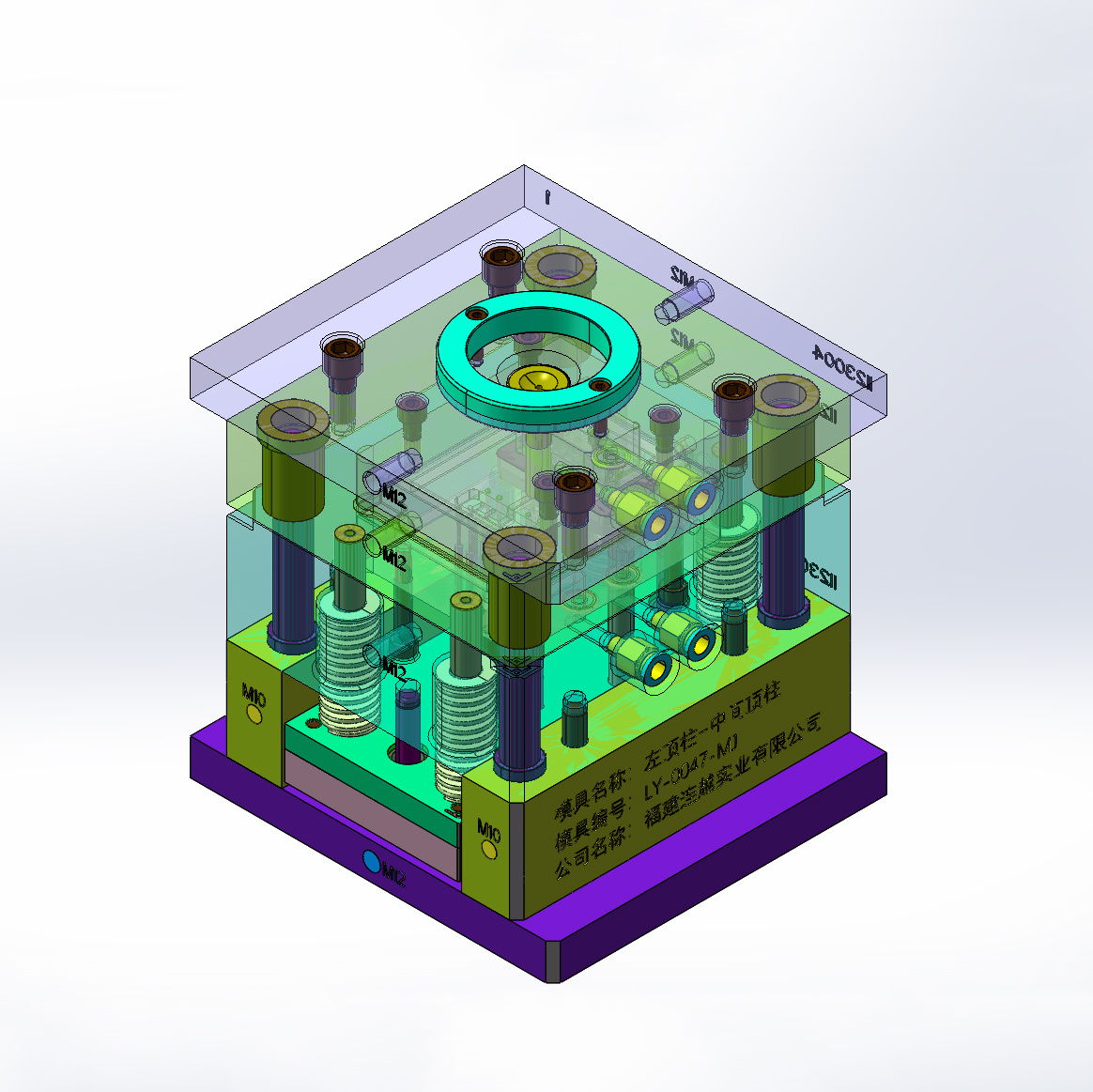

Master the core key technologies of precision mold design, simulation analysis and manufacturing and molding technology

Manufacturing

Machining Center

The processing center has the advantages of stable processing quality, high processing accuracy, high repeated accuracy, high processing of complex faces, high processing efficiency, etc., and provides reliable guarantee for the complex and diverse product needs of customers.

Diemaking Workshop

First -class precision mold manufacturing capabilities, provide precision injection molding molds, precision stamping molds and rubber molds for automotive appliances related products, and provide strong support for new product development

Injection Workshop

There are twenty small and medium -sized injection molding machines in the injection molding workshop, with monochrome to multi -color products injection molding capabilities

Stamping Workshop

There are fifteen precision advanced small and medium -sized stamping machine the the workshop, mainly stamping the stamping parts for our auto parts

PCBA Workshop

Equipped with new imported multi -function patch machines, high -speed patch machines, fully automatic tinnug paste printing machines, lead -free (nitrogen) return furnaces, wave welding, AOI detection, etc., focus on high -quality PCBA products production

Assembly Workshop

The company has a dust -free and electrostatic product assembly workshop, equipped with an advanced intelligent manufacturing management system to escort the first -class quality of automotive electronic electrical products

Honor

16949

ROSH

CE

Quality Report

Culture

Enterprise spirit:Unity, pragmatism, speciality and efficient.

Business philosophy

To form a community of interests with customers, suppliers, and employees

Marketing concept

Create value for customers with high-quality products.

Quality policy

Based on product quality, and guaranteed by speciality service.